Continuous Flow Analyzer Flow Star I

Category:

Key words:

Working principle

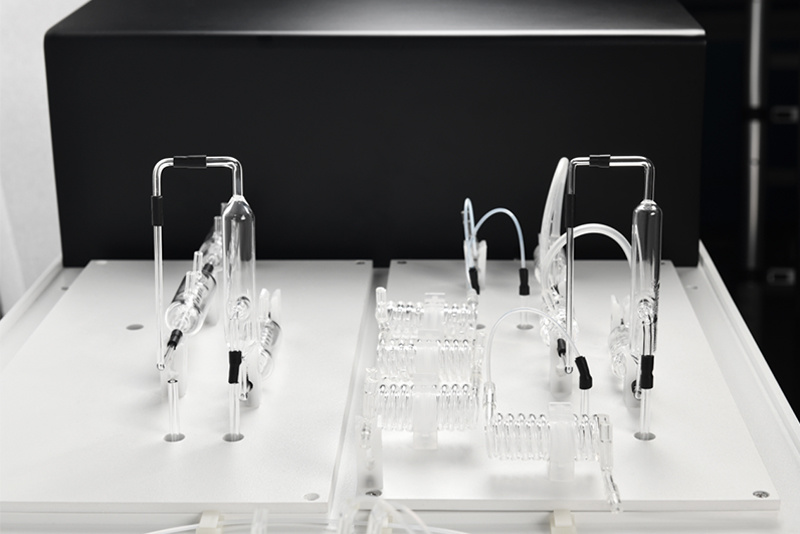

The continuous flow chemistry analyzer consists of five parts: an autosampler, a high-precision peristaltic pump, a chemical analysis module, a colorimeter, and a data processing system.

The autosampler is controlled by a computer program and takes out the sample accurately according to the pre-set sampling procedure (including location, sampling time, cleaning time). The high-precision peristaltic pump accurately and quantitatively delivers samples and reagents. The peristaltic pump quantitatively injects the reagents into the chemical reaction module according to the order of curing in advance, and uniform air bubbles are injected into the chemical analysis module at the same time, and each sample is divided into 20-30 segments of samples with the same composition. Samples and reagents are mixed by rotating up and down through the inert glass ring in the chemical analysis module, filtered and diluted by passing through the dialyzer, accelerated reaction by heating through the thermostat, distilled by passing through the online distiller, digested by passing through the online digester, extracted by passing through the phase separator, developed color by reacting with the developer, etc. All reactions were completed in the chemical analysis module. The colored liquid is then driven to a colorimeter for colorimetry. The control software records the peak height and compares it with the standard curve to calculate the concentration. Because the system is constantly flowing and the autosampler is constantly sampling, you can see a steady stream of measurements for each sample on the computer screen.

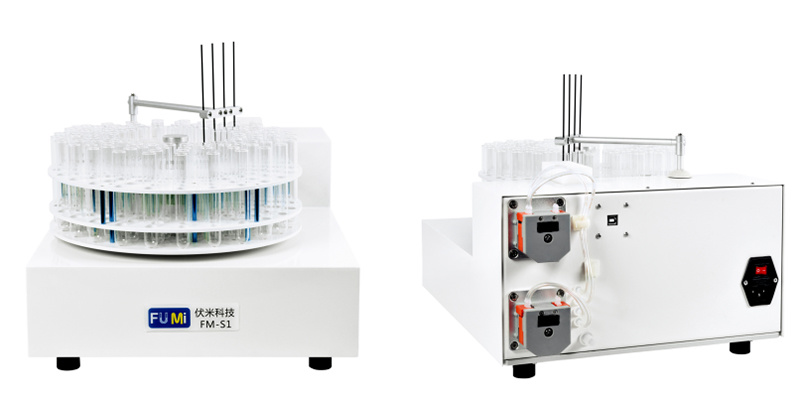

Random Autosampler FM-S1

Can be equipped with 1-4 needle injection, disc design

• 100 10 mL sample tubes

• Built-in cleaning pump, computer speed, to ensure that the amount of cleaning water

• Multiple samples can be taken at any location for repeatability testing

• Computer software controls injection time and cleaning time

• USB interface

• Optional in-line ultrasonic device

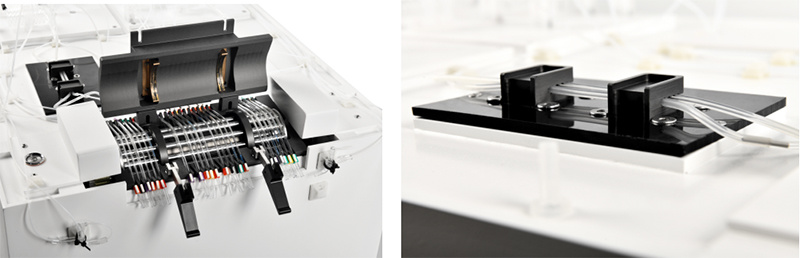

High precision peristaltic pump FM-P1

According to the demand configuration, provide 24,48,72 and other combinations for selection

• 1-2 air injection solenoid valve, using photoelectric induction control bubble injection frequency, the same as the peristaltic pump rotation frequency

• Each solenoid valve can be fitted with four-way air injection

• Error 0.5 per hour

• Each liquid fragment has the same volume and the same reagent/sample ratio, thus ensuring a high degree of reproducibility

• Peristaltic pump rotation speed controlled by computer software, infinitely variable speed

• Speed range: 0-200 r/min minutes

Chemical Analysis Module

Leakage outlet pipe, leakage can be discharged by itself, will not affect the equipment

The mixing ring is made of chemically inert glass, anti-corrosion, and can clearly observe the internal reaction and bubble pattern rules, easy to maintain and check

• The mixing ring is made of glass with very small tolerances to ensure a high degree of repeatability and accurate flow delivery. 2mm inner diameter to avoid clogging of dirty samples

• On-line distiller, on-line digestion, on-line dialysis, on-line extraction, on-line constant temperature and other sample pretreatment devices are all loaded on the chemical analysis module

• The system adopts the network interface DHCP (Dynamic Host Configuration Protocol) to connect with the computer and directly control the chemical host

high precision digital colorimeter

• Dark room color comparison ensures the lowest noise and drift

• 32-bit high-precision digital to analog conversion, online electronic bubble removal and post electronic bubble removal recalculation

• The light source adopts a monochrome LED environmentally friendly and energy-saving cold light source, greatly extending the life of the light source

• Equipped with a drainage pipeline, any leakage can be automatically discharged without damaging the colorimeter

• Dual beam principle, automatic blank calibration, ensures extremely low drift even at extremely high sensitivity

• No need for filters, users don't have to worry about filter mold growth due to humidity, bacteria, or dust causing transparency issues. There is no need to follow the operation and maintenance steps of storing the filter in a dryer after each measurement task is completed

• Multiple sizes of colorimetric pools, with 50mm as standard

• Seismic design, convenient for working on ships and in vehicles

• Don't worry about mechanical failures and temperature effects

• No need to manually adjust baseline, sensitivity, gain, and luminous flux, fully controlled by computer software

• Automatic alarm in case of malfunction

• The view will change with the concentration of the sample, and all peaks are within the view

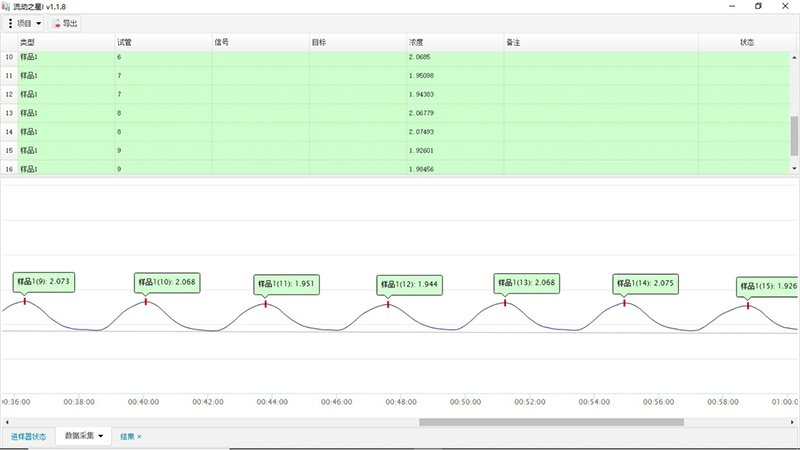

Mobile Star I system operation control software

• Operation under WINDOWS 10 and above

• Chinese operation interface

• Calibration curves are automatically stored and can be recalled repeatedly

• Automatic calculation of minimum detection limit

• System software can control eight channels four hosts

• The system software can control the setting of four peristaltic pumps and the temperature setting and control of eight thermostatic heaters 0-200 degrees Celsius

The system software can choose to use peak height or integral area calculation results for each channel, which is particularly important for the recovery rate of anionic synthetic detergents.

Optional functions

Built-in color touch screen microprocessor controller; Realize real-time monitoring and display of the operating status, temperature, leakage monitoring, remaining life of light source and consumables replacement reminder of various components of the equipment (pump speed, distillation, digestor); Automatically allocate IP to each component;

Product Consulting

You can submit the following information to contact us, we will contact you within one business day, please pay attention to your email.

Related Products